After a few promises to the wife that we would soon be millionaires, and that I’d never ask for another dime, I placed my order for a 3.8 watt.

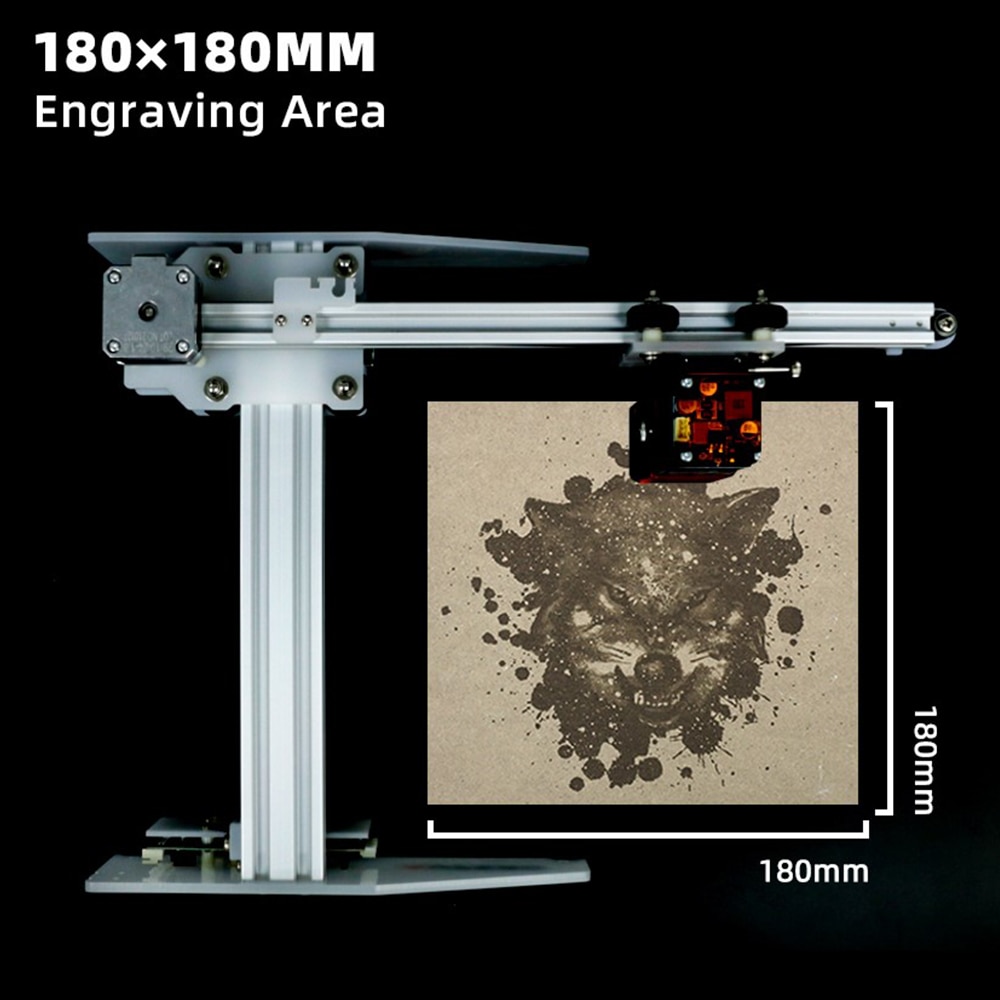

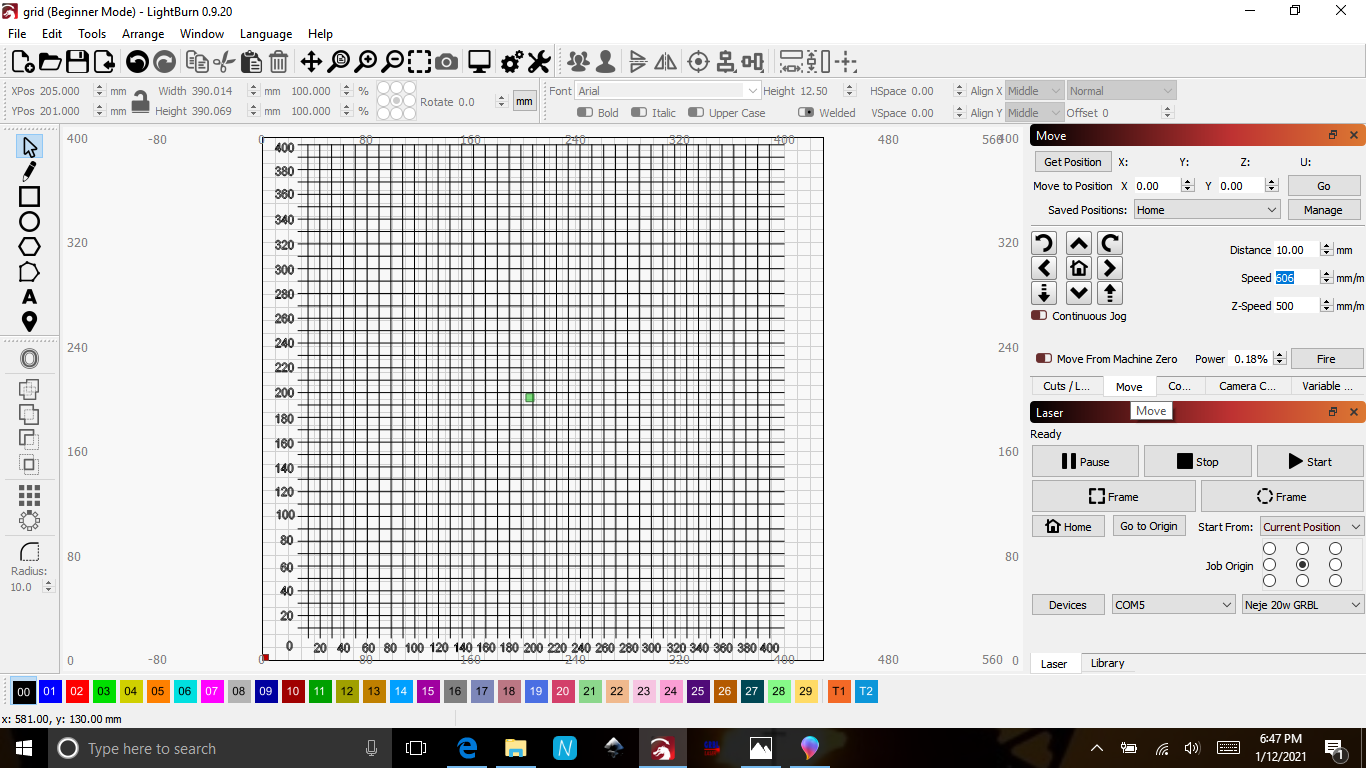

Several forum posts referenced a company called JTech, who had a plug-n-play kit specifically for my Shapeoko. What if I wanted to make something BIG? Hey! They have lasers for CNC machines and 3D printers! Research, research, research… But which one? There were those Chinese K-40 types on eBay, but the beds were too dinky. “Honey… I need a laser!” It wasn’t bad enough that I had just spent two grand. Pushing the feeds ‘n’ speeds to near bit-snapping levels, one stinkin’ $10 ornament in 1/4” ply took over an hour! Couldn’t make any money at that rate. I had some really tiny bits which oughta cut the intricate detail, so we bought several pattern files, chose one design, and proceeded to cut. Those Christmas tree ornaments looked wonderful. I have an extensive graphics background (vector/bitmap) but, since we were already poking around on Etsy, why not save time (money) and use something someone else had already designed? (FYI: Dozens of reasons.) So, we keyed “Christmas CNC” into their search bar, and voila! 1,716 results. We bought our unit in the fall, so had (overly) ambitious plans to make a bunch of Christmas-themed items. So, whatcha gonna make? Signs, boxes, desktop organizers, furniture, earrings, aluminum parts… The possibilities are positively mind-boggling!įor my wife and me, the primary goal was to make wooden products to sell on Etsy. You bought a slew of bits to do any job imaginable, theoretically. So, you’ve bought and assembled your shiny, new CNC (in my case, a Shapeoko 3 XXL), and are ready to get to work. LightBurn story by John Walker All you need to know about LightBurn software – main features

0 kommentar(er)

0 kommentar(er)